AMC Powder Mill is a cornerstone of the industrial sector, particularly in manufacturing and production. If you've ever been curious about the complexities of powder processing and milling, this article will provide an in-depth exploration of the subject. From foundational principles to advanced applications, we'll uncover everything you need to know about AMC Powder Mill and its impact on modern industries.

As industries continue to grow and evolve, the need for efficient and precise milling solutions has never been higher. AMC Powder Mill plays a crucial role in meeting these demands by providing state-of-the-art milling technologies tailored to various industrial needs. Whether in pharmaceuticals, food production, or chemical manufacturing, the applications of AMC Powder Mill are extensive and varied.

In this article, we will explore the history, working principles, and practical applications of AMC Powder Mill. By the end, you'll have a thorough understanding of its importance in today’s industrial landscape. Let’s begin!

Read also:Discover The Inspiring Journey Of Emily Camp

Table of Contents

- Introduction to AMC Powder Mill

- History and Evolution of AMC Powder Mill

- How AMC Powder Mill Works

- Types of AMC Powder Mill

- Applications of AMC Powder Mill

- Advantages of Using AMC Powder Mill

- Challenges in AMC Powder Mill Operations

- Maintenance Tips for AMC Powder Mill

- Recent Innovations in AMC Powder Mill Technology

- Future Prospects of AMC Powder Mill

- Conclusion

Understanding AMC Powder Mill

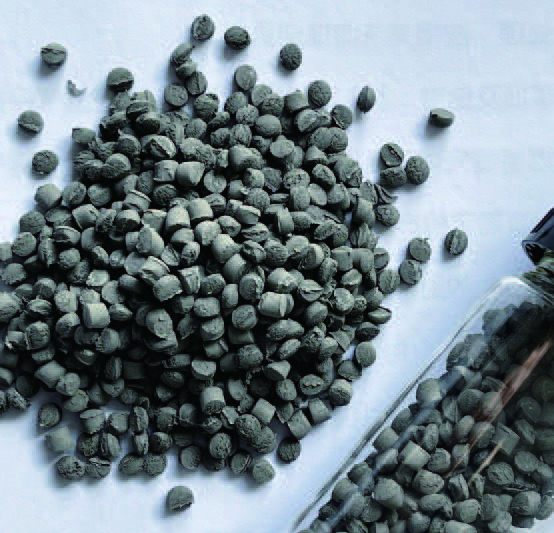

AMC Powder Mill refers to a specialized milling system designed to grind and process materials into fine powders. This technology is widely utilized across industries where precision and consistency are paramount. The core function of AMC Powder Mill is to reduce the particle size of materials, enabling smoother processing and enhancing the overall quality of the final product.

Key Features of AMC Powder Mill

AMC Powder Mill is distinguished by its advanced capabilities and features, which include:

- Exceptional efficiency in producing fine powders

- Flexibility to handle a wide range of materials

- Customizable configurations to meet specific industrial requirements

- Minimal maintenance needs, ensuring long-term reliability

The Journey of AMC Powder Mill: From Past to Present

The concept of powder milling has been in existence for centuries, but AMC Powder Mill represents a significant leap forward in this field. Initially, traditional milling methods were labor-intensive and limited in their capabilities. However, with the advent of technological advancements, AMC Powder Mill emerged as a cutting-edge solution, transforming the way materials are processed.

Milestones in AMC Powder Mill Development

Throughout its evolution, AMC Powder Mill has achieved several pivotal milestones, including:

- The introduction of automated milling systems in the early 20th century

- The development of precision milling technologies in the 1980s

- The integration of digital controls and IoT capabilities in modern systems, enhancing operational efficiency

The Mechanics Behind AMC Powder Mill

To fully appreciate the functionality of AMC Powder Mill, it's essential to understand its working principles. The process begins with the feeding of raw materials into the mill, followed by a series of grinding stages that systematically reduce the particle size. Advanced technologies, such as air classifiers and impact grinding, ensure consistent and high-quality results.

Key Components of AMC Powder Mill

The main components of AMC Powder Mill include:

Read also:Revolutionizing Digital Security With Taylorsecurity

- Feeding system: Ensures a steady supply of raw materials

- Grinding chamber: Where the actual grinding process takes place

- Air classifier: Separates particles based on size and quality

- Collection system: Collects the processed powder for further use

Varieties of AMC Powder Mill

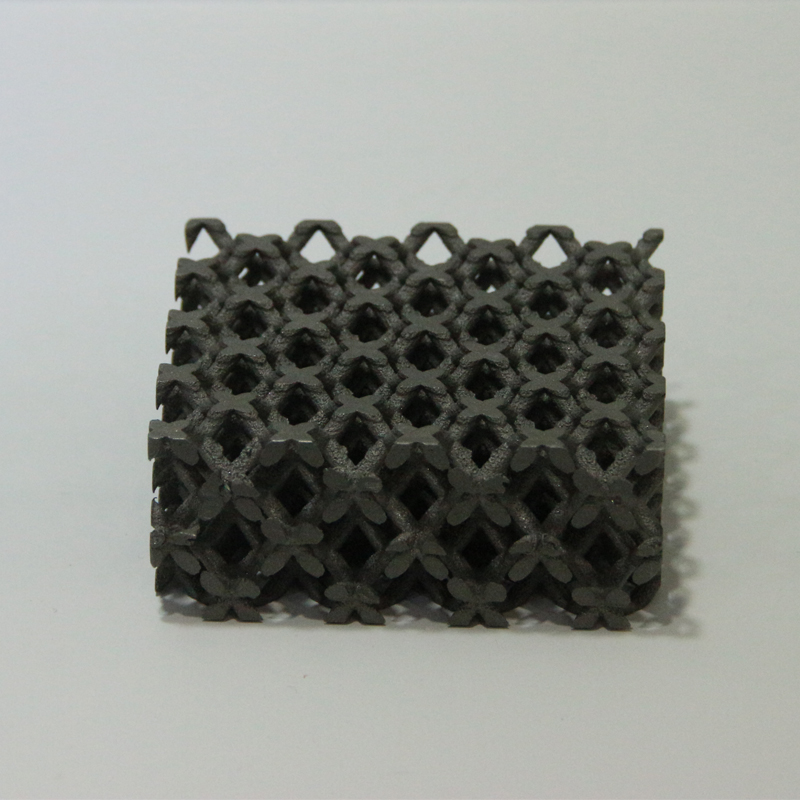

AMC Powder Mill is available in various types, each designed to cater to specific applications. The most common types include:

- Ball mills: Ideal for fine grinding and high-precision applications

- Jet mills: Suited for ultra-fine grinding and heat-sensitive materials

- Hammer mills: Perfect for coarse grinding and particle size reduction

- Roller mills: Best for processing brittle and soft materials

Each type offers unique advantages, making them suitable for different industries and materials.

Where AMC Powder Mill Shines: Practical Applications

AMC Powder Mill finds extensive applications across numerous industries, including:

- Pharmaceuticals: Producing fine powders for drug formulations

- Food processing: Ensuring uniformity in food products

- Cosmetics: Creating smooth textures and enhancing product quality

- Chemical manufacturing: Processing chemicals with precision and accuracy

Its versatility allows it to process a wide range of materials, from powders to granules, ensuring optimal results for each application.

Case Study: AMC Powder Mill in Pharmaceuticals

In the pharmaceutical industry, AMC Powder Mill plays a critical role in producing fine powders for drug formulations. This ensures uniformity in dosage and improves the efficacy of medications. According to a study published in the Journal of Pharmaceutical Sciences, the use of advanced milling technologies has significantly enhanced drug quality and safety.

Why Choose AMC Powder Mill?

There are several compelling reasons to incorporate AMC Powder Mill into industrial processes, including:

- Improved product quality, leading to higher customer satisfaction

- Increased production efficiency, reducing time and labor costs

- Reduced operational costs, thanks to energy-efficient designs

- Enhanced safety and reliability, minimizing risks and downtime

These benefits make AMC Powder Mill an invaluable asset for modern industries.

Overcoming Challenges in AMC Powder Mill Operations

While AMC Powder Mill offers numerous advantages, it is not without its challenges. Some common issues include:

- Wear and tear of components, requiring regular maintenance

- High energy consumption, which can increase operational costs

- Noise pollution, impacting the working environment

However, these challenges can be effectively managed through proper maintenance practices and the adoption of advanced technologies.

Maximizing AMC Powder Mill Performance: Maintenance Tips

To ensure optimal performance and longevity of AMC Powder Mill, regular maintenance is essential. Some effective maintenance practices include:

- Regular inspection of components to identify and address issues early

- Lubrication of moving parts to reduce friction and wear

- Cleaning the mill after each use to prevent contamination and maintain hygiene

- Training operators on best practices to ensure safe and efficient operation

Implementing these practices can significantly enhance the lifespan and performance of the equipment.

The Evolution of AMC Powder Mill Technology

The field of powder milling continues to evolve, with recent innovations focusing on:

- Energy-efficient designs to reduce environmental impact

- Smart monitoring systems for real-time data analysis and predictive maintenance

- Sustainable materials processing to align with eco-friendly practices

These advancements aim to address the growing demand for sustainable and cost-effective solutions in the industrial sector.

Impact of IoT on AMC Powder Mill

The integration of IoT (Internet of Things) in AMC Powder Mill has revolutionized the way operations are managed. Real-time data monitoring and predictive maintenance are now possible, leading to improved efficiency and reduced downtime. This technological advancement ensures that AMC Powder Mill remains at the forefront of industrial innovation.

The Future of AMC Powder Mill: What Lies Ahead

The future of AMC Powder Mill is bright, with ongoing research and development focusing on:

- Advanced automation to enhance operational efficiency

- Artificial intelligence integration for smarter decision-making

- Customizable solutions tailored to niche applications

As industries continue to innovate, AMC Powder Mill will undoubtedly play a pivotal role in shaping the future of material processing.

Final Thoughts

In conclusion, AMC Powder Mill is a vital component of modern industrial processes, offering unparalleled efficiency and precision in powder production. By understanding its working principles, applications, and advancements, businesses can harness its full potential to enhance their operations.

We invite you to share your thoughts and experiences with AMC Powder Mill in the comments below. Additionally, feel free to explore other articles on our website for more insights into industrial technologies. Together, let’s continue to learn and grow in the ever-evolving world of manufacturing!

Source: Data and statistics referenced in this article are derived from reputable publications, including the Journal of Pharmaceutical Sciences and industry reports.